We have our resources, methodologies and creativity to satisfy your specific requirements through our products

.

We have our resources, methodologies and creativity to satisfy your specific requirements through our products

.

Our teams are a young, multidisciplinary and multinational group, made up of professionals from different areas with extensive experience in the ceramic sectors.

We believe in proximity to the customer: proximity brings trust, achieves faster and more effective solutions and ultimately reduces costs.

R&D&I

COLOR ESMALT ‘s R&D Department leads innovation in ceramic glazes and inks, with a clear focus on high value-added solutions that combine quality and differentiation.

Among its main lines of work are the development of enamels with metallic effects, single-firing polishes and products with advanced chemical and physical resistance properties. This commitment to innovation is backed by a solid portfolio of patents, which certifies the department’s capacity to generate exclusive and cutting-edge solutions.

The patents developed by the team cover a wide spectrum of advances, from oxide-based compositions to special pigments for metallic glazes, as well as a whole range of special inkjet inks: metallic, glossy, matte with high transparency, etc. These inventions reflect our ongoing commitment to applied research and the improvement of the technical and aesthetic properties of ceramic materials.

In addition, the R&D team works closely with leading technology centers to improve production processes, develop new ranges of frits and explore innovative decorative effects. This effort is complemented by the use of domestic raw materials, meeting the highest standards of quality and sustainability.

Installation of our first granilla manufacturing plant

In 2005, we took a decisive step in our trajectory with the installation of our first granules manufacturing plant. From the outset, this plant was designed to achieve high outputs without compromising quality, guaranteeing exceptional uniformity in each batch. Thanks to precise process control, we offer particle size distributions in any range, adapting to the specific needs of each customer and application.

Expansion with the ink-jet ink plant

In 2011, we consolidated our commitment to innovation with the installation and start-up of our ink-jet ink manufacturing plant. This new infrastructure allowed us to offer advanced solutions for digital decoration, combining stability, performance and a wide chromatic range. With this, we reinforce our commitment to the ceramic sector, providing high precision products adapted to the latest printing technologies.

Innovation in metallic enamels and inks

Between 2004 and 2007, we registered our first patents for metallic-effect glazes, marking a milestone in ceramic surface innovation. This breakthrough laid the groundwork for the development of new technologies, culminating in 2012 with the launch of the first patented metallic effect ink-jet ink. This innovation was a world first that revolutionized digital ceramic decoration, enabling the reproduction of metallic finishes with a precision and versatility never seen before, and consolidating our leadership in the sector.

Recognition of innovation: Alfa de Oro Award

Our commitment to research and development was recognized in 2017 with the award of a prestigious Alfa de Oro prize at the Valencia ceramics fair. This award highlighted our work in the development of an innovative protective matte ink, characterized by its high transparency and exceptional mechanical resistance to surface abrasion. This breakthrough was an important milestone in the protection and finishing of ceramic surfaces, reaffirming our leadership in technological solutions for the sector.

Commitment to sustainability: solar energy for our plant

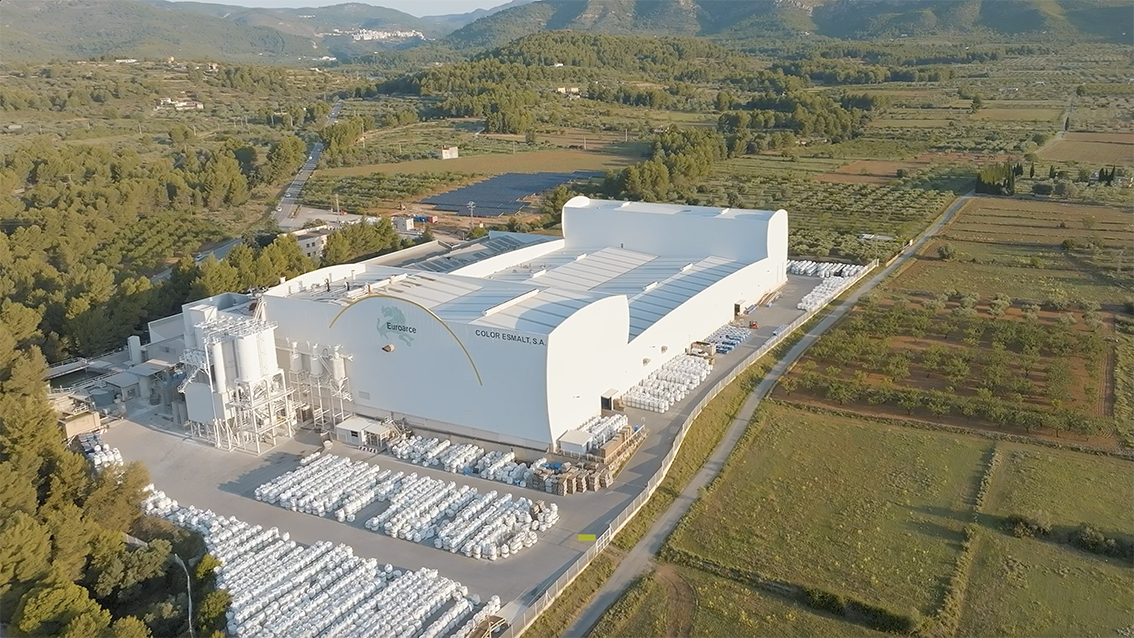

Aware of the importance of sustainability, in 2023 we installed a solar panel park to supply energy to our plant. This initiative will enable us to significantly reduce our carbon footprint and move towards a more efficient and environmentally friendly production model. Thanks to this investment in renewable energies, we reinforce our commitment to responsible innovation and energy efficiency in the ceramics industry.

Expansion and leadership in the sector

In 2024 COLOR ESMALT took a decisive step forward by further integrating into EUROARCE the SAMCA group company, the undisputed leader in the supply of ceramic raw materials. This integration has allowed us to consolidate our presence in the market, expanding our capacity to offer high value-added solutions and reinforcing our commitment to innovation and excellence in the ceramic industry.